|

||

Zsolt Kovacs | ||

|

associate professor Department of Materials Physics, Eotvos Lorand University | ||

| E-mail: | kovacs.zsolt@ttk.elte.hu | |

| Address: | H-1117 Pazmany Peter setany 1/a, Budapest, Hungary | |

| Room: | 4.65 | |

| Tel: | 6218 | |

Selected research topics

-

Effect of severe plastic deformation on metallic glasses

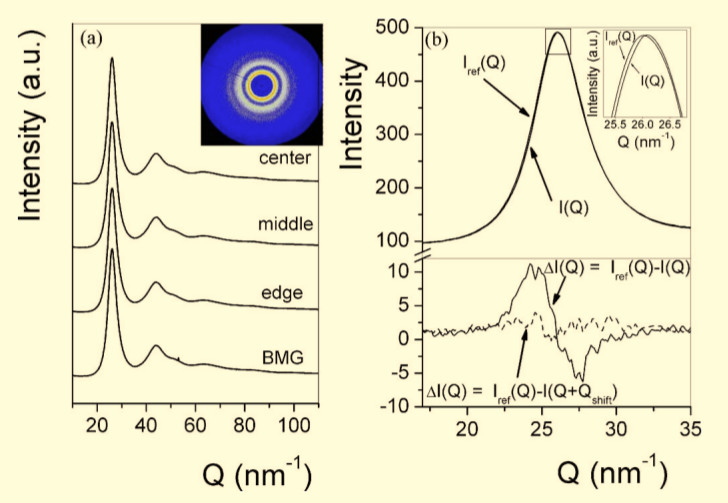

| Metallic glasses are metastable materials, which exhibit some structural variability. Among the firsts, we applied severe plastic deformation to change the atomic structure of these materials while maintaining cohesion in the bulk samples. We proved that deformation can induce primary crystallization in a thermally non-primary crys- tallizing metallic glass. Using high stability synchrotron X-ray radiation (figure), we revealed that plastic deformation produ- ces anisotropy in bulk metallic glasses. |

|

|

|

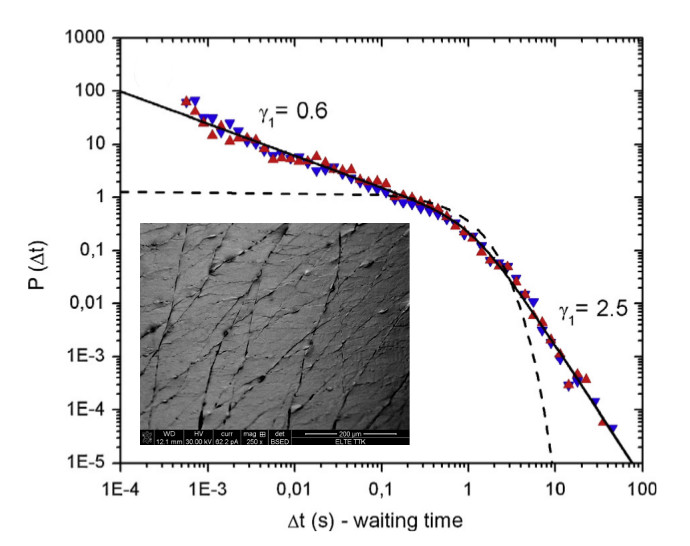

We proved experimentally, that metallic glasses can deform plastically in stable and unstable ways at the same temperature. Based on the emitted accustic emission signal of the unstable deformation mode, we first separated deformation stages in a metallic glass. Although the acoustic signal changed strongly between the subsequent stages, a common power law behavior can be identified for time and amplitude distributions of the accoustic events. | |

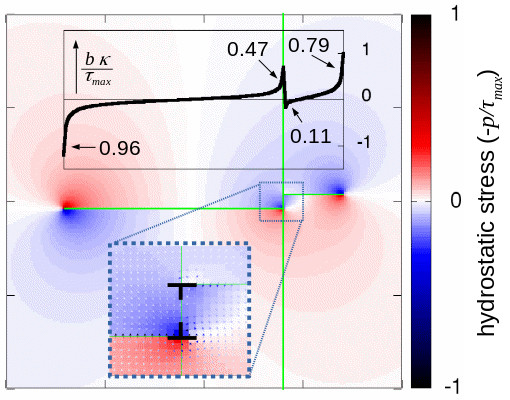

| Bulk metallic glasses tend to break instantly along the first forming shear band. In different experimental works we produced large plastic deformation with multiple shear bands using torsional deformation at both high and ambiant pressures. These shear bands often intersect each other and exhibit an interaction through the local stress field. We analyzed accurately the offset distribution and stress field at a shear band intersection and first identified a diffusion process of volumetric faults, which has a key role in shear band interaction and localization. |

|

|

|

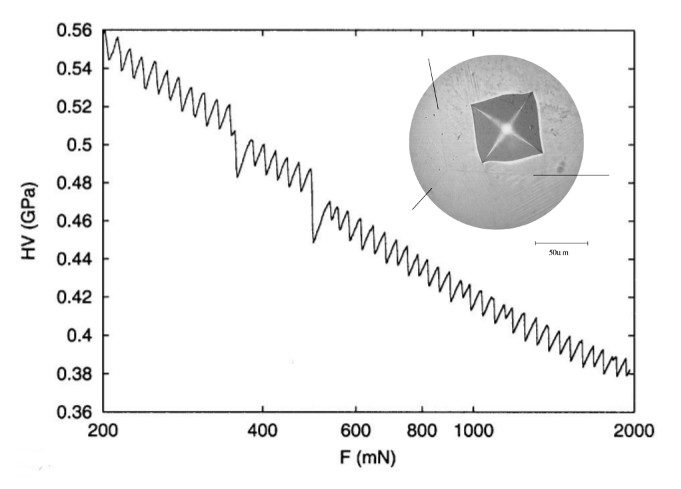

Alloys which contains solute atoms often show deformation rate sensitivity and exhibit plastic instabilities in a specific deformation rate range. This efect is called the Portevin-Le Chatelier effect and it bases on the interaction of solute atoms and dislocations. In these insta- bilities, we identified a mode change, which originates from deformation localization and enhanced fluctuations near the yield point. We also proved that both crystal orientation and boundaries between grains have effect on the plastic instabilities in micrometer scale. | |